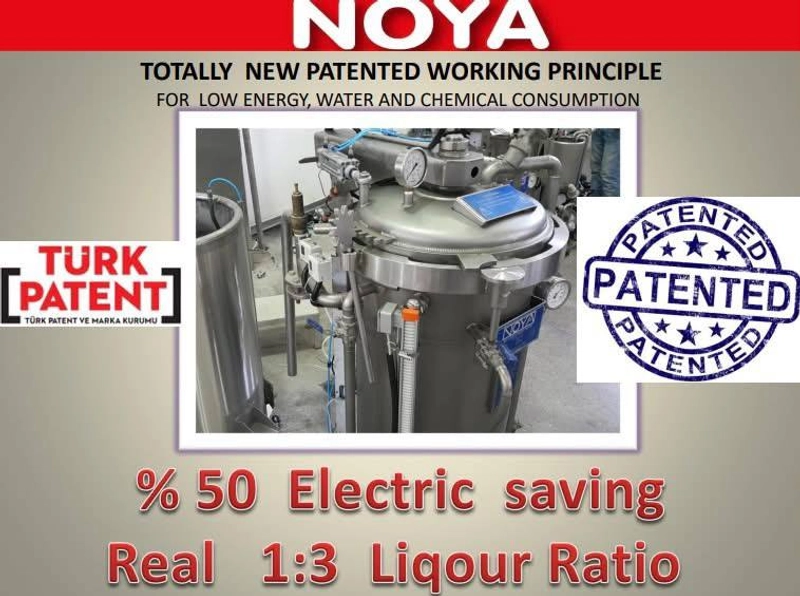

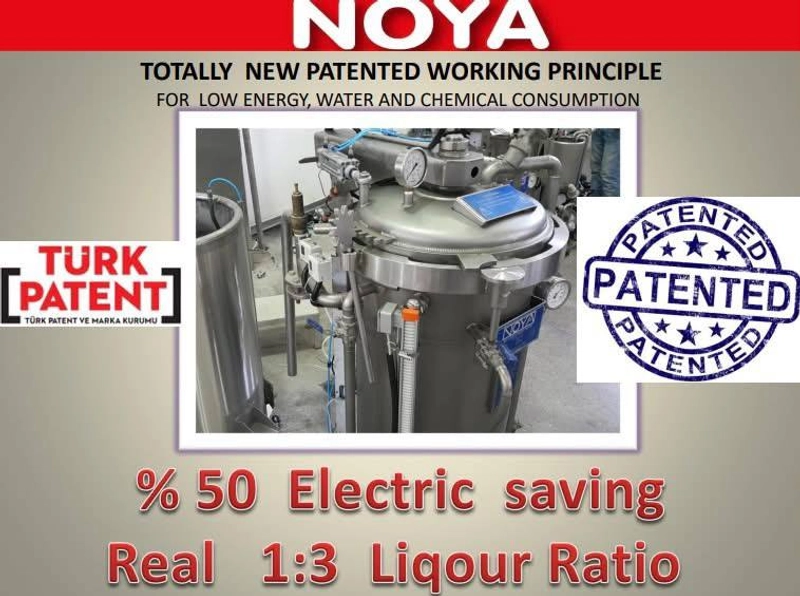

纱线染色机(专利系统)

产品价格

价格面议

纱线染色机(专利系统)

Noya Mekatronik

产品详情

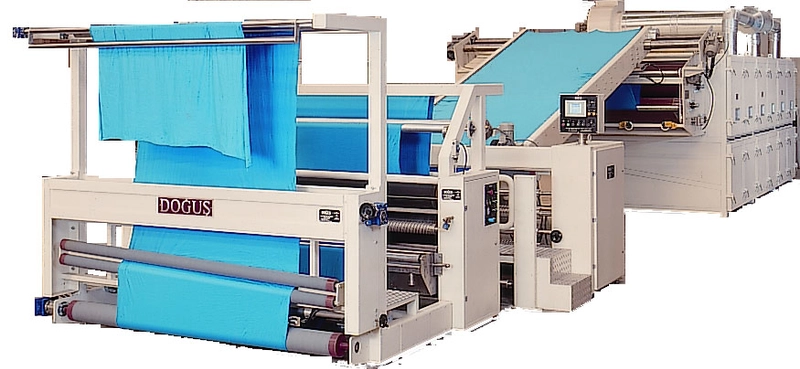

HT 纱线染色机是根据以下方面的最新技术和技术改进而设计的:液体流量、液体循环和最大效率。 机器可以使用不同的合适载体来加工许多不同种类的材料,例如线轴包装、罩子、横梁、松散的材料、顶部等。

规格

TECHNICAL ADVANTAGES Perfect dyeing results without having unlevelled dyeing effect for max. 2 kg bobbins in weight. Inside/outside and outside/inside two way flow without changing the direction of the snail pump motor. Short and fast heating times by efficient heat exchanger Dyeing capacity of min 50% and max. 100% with air pad system Perfect dyeing possibility on every pressure with differential pressure transmitter Repeatability by automation system Short dyeing times with the help of 100% reserve tank Liquor ratio in between 1:5 - 1:8 Single or double material carrier Heat exchanger in the circulation pipe line Rapid lid opening, closing, locking system Heavy duty stainless steel centrifugal pump with mechanical seal. DRYING PROCESS CONSISTS OF 3 SEQUENCES; HYDROEXTRACTION: replaces centrifugal operation and is done directly after loading of wet yarn carrier coming from dyeing machine. DRYING: Drying process starts automatically alter hydroextraction. The air is blown by the blower through heat exchanger for heating, heated at preset temperature according to yarn type and colour shade, flows at high speed through the yarn 1/0 direction, thereby transferring heat to the yarn and saturating with evaporated water. Duration of drying phase is preset on the base of air temperature at inlet and outlet of yarn packages 3 - YARN CONDITIONING: After the drying phase, air is circulated O/l direction in order to equalize residual humidity in yarn packages and reduce the temperature of the yarn. ADVANTAGES: No need of centrifuge hydro extractor. Loading and unloading is the waste time and also yarn packages may be damaged during loading /unloading. Process time is 50% to 70% shorter due to closed loop. Labour is dramatically reduced in the whole drying process.

装运港

土耳其

Izmir Port

联系供应商

该供应商的更多产品

类似产品

钮扣机

探索我们专为高效、精确地生产纽扣而设计的纽扣机系列。从手动到自动选项,我们的机器可以满足各种制造需求。无论...

MANUFATURA DE BOT...

缝纫机之字形针板

缝纫机 Zig-Zag 针板是精密设计的零件,在实现平滑而准确的曲折缝合方面起着重要作用。它由高品质、耐用...

M/S MAKALI MANUFA...

缝纫机竞赛戒指

缝纫机竞赛环是确保缝纫机平稳高效运行的重要组件。这款戒指由高品质、耐用的金属制成,旨在承受持续使用并提供持...

M/S MAKALI MANUFA...

缝纫机螺丝

缝纫机螺丝是必不可少的硬件组件,用于牢固地固定和固定缝纫机的各个部件。这些螺钉由高质量的防锈金属制成,具有...

M/S MAKALI MANUFA...

气球挤压机

水力提取器有四个主要功能,如下所示。染色后用绳子挤压成型织物,然后放松烘干。通过在磁性担架上过度喂食,它可...

Noya Mekatronik

Air Relax 烘干机

Air Relax Dryer 的主要逻辑是在开幅和管状织物上提供具有出色收缩率的优质干燥效果,不会产生张...

Noya Mekatronik

Pin Chain 空气放松烘干机

Pin Chain Air Relax 干燥机的主要目的是为开口宽度和管状织物提供优异的收缩率和优异的干燥...

Noya Mekatronik

纱线染色机(专利系统)

HT 纱线染色机是根据以下方面的最新技术和技术改进而设计的:液体流量、液体循环和最大效率。 机器可以...

Noya Mekatronik

管状热定型机(专利)

管状热定型机-第一台具有 3 个腔室长度和令人印象深刻的 LED 照明的机器! 织物担架:长度为 6000...

Noya Mekatronik

钢辊、钢针

钢制滚轮,尺寸,材料可定制,可定制。批量生产。

KN STEEL BALL